Reverse Osmosis Filtration System

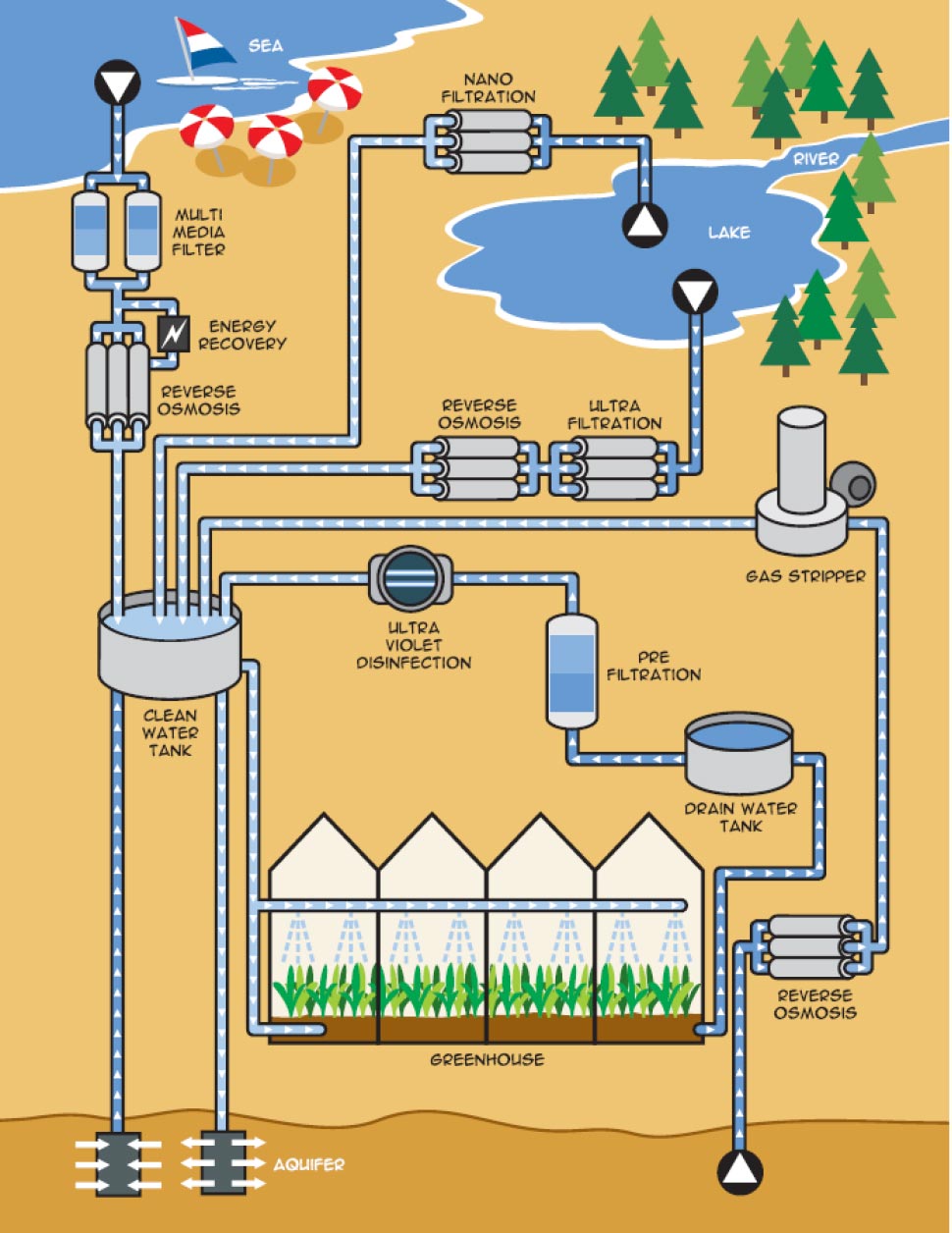

The RO – reverse osmosis filters offered by us are used for the purification of well water. Our system does NOT require any softening of water against osmosis or the use of any chemical compounds! With this system, the effluent water does not contain any compounds harmful to the environment. The performance of the filters is custom set according to client needs. The reverse osmosis filter system is built in terms of the need for chemically clean water as well as depending on the quality of the well’s own water. RO filters with capacity of 4, 15 and 30 m3 of clean water per hour already work in Poland. Purified water has an EC of 10-20 μS / cm3 and after cleaning it does not contain any impurities or chemical compounds, has properties similar to distilled water.

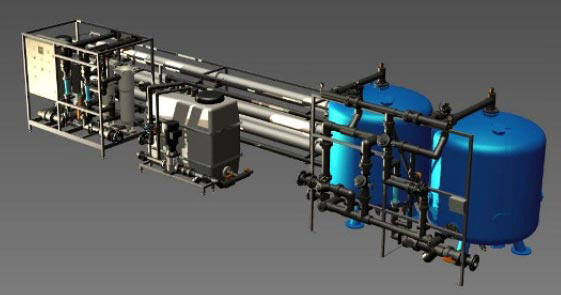

Before passing through the right filter with osmotic membranes (semi-permeable membranes), the water should be pre-cleaned of possible mechanical impurities. In the first stage it is passed through a system of two mechanical filters with a triple bed (MMF filter). There solids are deposited that could damage the osmotic membranes. Mechanical filters MMF also regulate the pressure of water entering and leaving the system. They are self-cleaning devices, cleaning starts automatically once a day. If the deep well borehole is deeper than 50 meters, you can opt out of the MMF filter.

After passing through the MMF filters, the water goes to the next ‘sack’ and ‘candle’ filters. In the first one it is filtered by a special nonwoven bag with a very high density, which prevents dust particles. The second is a system consisting of five candle filters (a single filter of this type resembles a spool with a wound string – see photo gallery below), water gets inside the “candle” and under pressure is pushed through its walls to the outside. The last two types of filters are enclosed in tanks because the cleaning is under pressure.

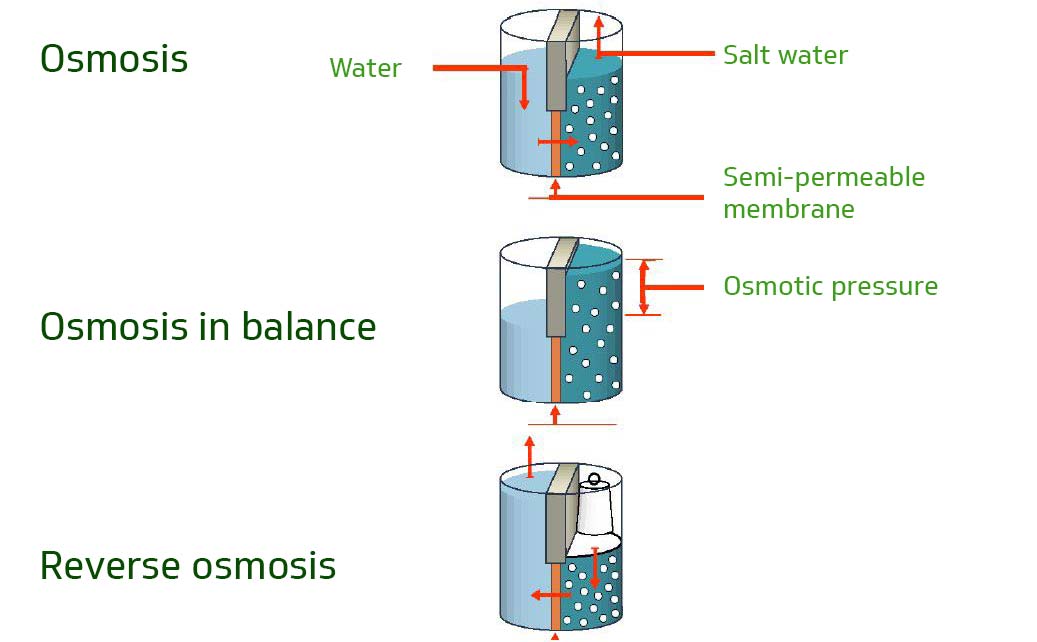

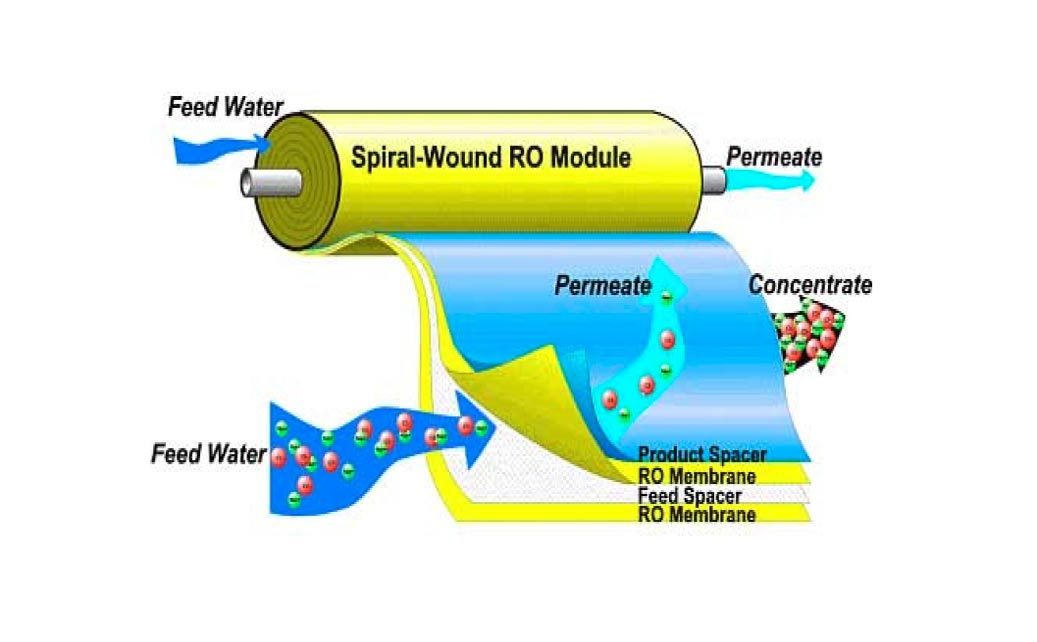

The pump then pumps the water completely free of mechanical impurities under very high pressure into reverse osmosis filters, the essential element of which are the beds of semipermeable membranes. In the process forced under reverse osmosis pressure, pure water molecules are separated from impurities.

From the filter, dirty water is directed outside into an earth sludge tank, in which it soaks into the ground and returns to the environment. The clean water goes to the tanks in the greenhouse or, if they are overflowing, to the rainwater reservoir. Such water is very well suited for irrigation of plants because it is devoid of minerals, which allows you to precisely compose the composition of the nutrient solution.

Osmosis purified water is also used for fogging greenhouses – due to the fact that there is no calcium and iron in it, there is no risk of clogging of the misting nozzles (with a very small diameter). Thanks to this the system works efficiently and correctly, creating very small water drops. When used for fogging ordinary well water after a certain time, lime deposits form on the nozzles and instead of fog the water begins to drip onto the plants. This worsens the health of plants, and on the leaves the drops form a sediment, which worsens the commercial value of ornamental plants. The water from the osmotic filter is also used to lower the temperature in the greenhouse – by special sprinklers the greenhouse roof is covered and when the water evaporates, the heat from the greenhouse is removed which results in lowering the temperature inside the building. In this case also the use of water free of mineral compounds prevents the formation of deposits on the glass.

Typically, the filters work around the clock and are only turned off when the sand filters are cleaned automatically or when the tanks are full. In addition, about half a year (depending on the quality and degree of contamination of well water) RO filters are chemically cleaned – the water cycle in the filter system is closed and the entire system is rinsed with a weak acid solution that cleans the filters from the deposits (on osmotic membranes micro- and macroelement deposits are formed). It is a convenient solution – client does not have to pay the costs associated with hiring professionals to clean the filters and with the help of this device he can do it himself. If the reverse osmosis filter is not used for a long time, it is flooded with water with a preservative and can be left in this way for half a year, without danger that the filter will be damaged in any way (e.g. by the development of microorganisms).

This device is controlled automatically. At the control panel that supports the filter, you can program a specific working time and monitor the work process on an ongoing basis. Any irregularities are also signaled (e.g. pressure drop in the pumps, stopping the work of the submersible pump, clogging of mechanical filters, or contamination of osmotic membranes).

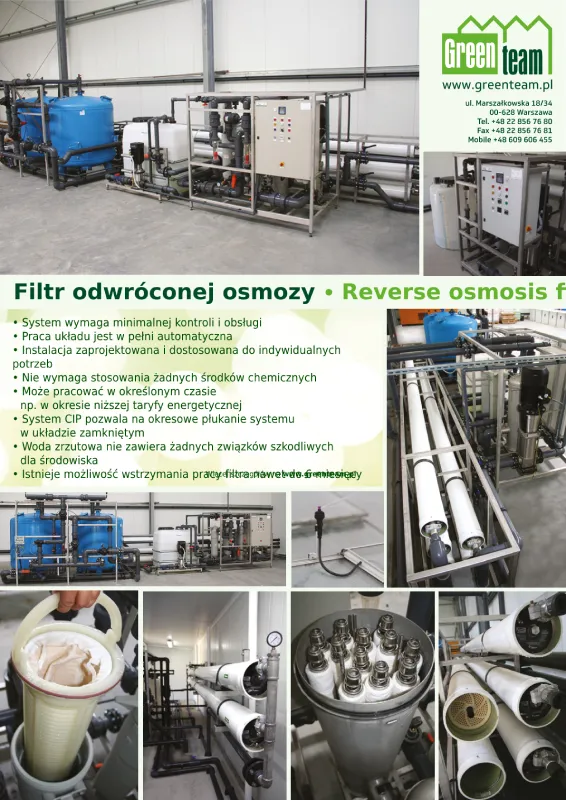

- The system requires minimal control and service;

- The system operation is fully automatic;

- Installation designed and adapted to individual needs;

- Does not require any chemicals;

- It can work at a certain time, e.g. during a lower energy tariff;

- CIP system allows periodic rinsing of the system in a closed system;

- The discharge water does not contain any compounds harmful to the environment;

- It is possible to suspend the filter for up to 6 months;

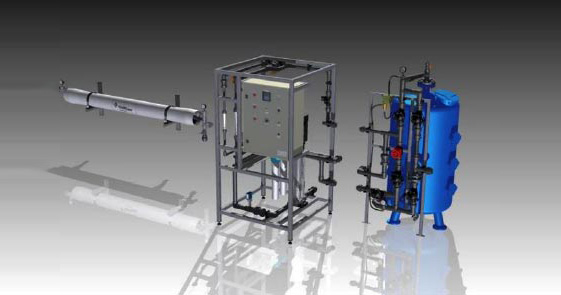

Reverse osmosis system with filtration and cleaning equipment

Our reverse osmosis system is custom based

Operation of reverse osmosis system

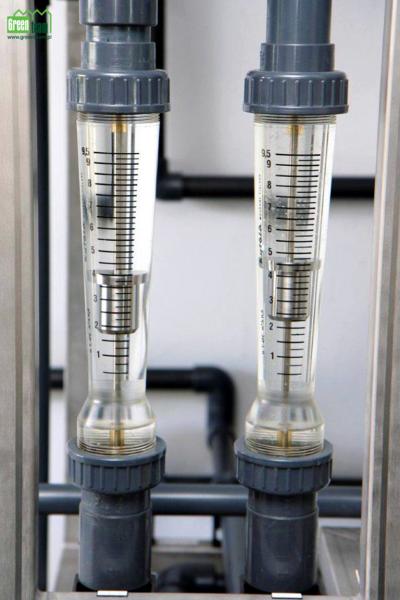

Water flow through reverse osmosis membranes

Reverse osmosis system. Capacity of 360 m³ per day.

Installation of reverse osmosis with a capacity of 360 m³ / day. Desalination min. 98% of tank or tap water. Includes – conductivity meter (EC) and timer for automatic water production out of peak hours.

Installation of reverse osmosis with a capacity of 15 m³/h

Instalation of MMF filters (Multi Media Filter) with a capacity of 30 m³/h