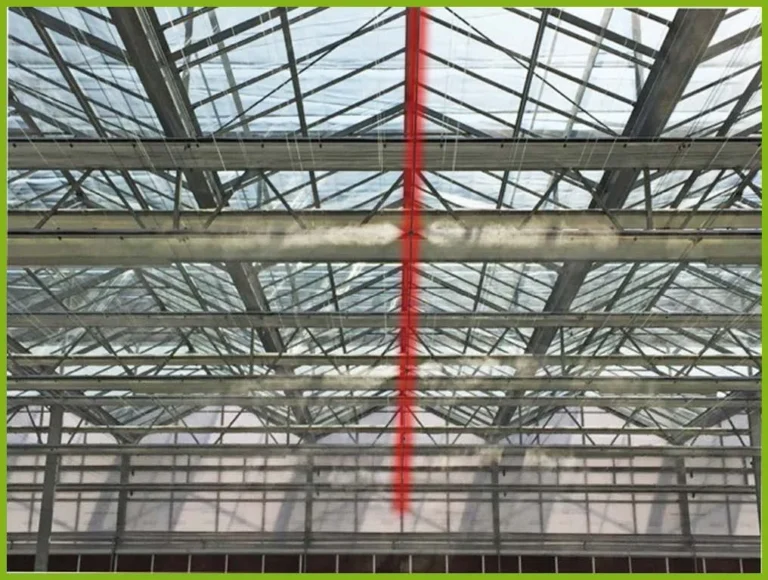

The following videos of our exemplary implementations of fogging systems

Green Team company offers a professional fogging system for use in crops under shelters.

The system offered by Green Team is made entirely of stainless steel. This applies to the main supply lines, all fasteners as well as the entire emitters equipped with ceramic nozzles.

The fogging system includes a wide range of products and solutions to meet the needs of the customer who wants a quality product to manage the perfect climate inside a greenhouse or other enclosed facility.

For high-pressure fogging system we offer different solutions, depending on the market, needs and capabilities of the customer.

“A-Line” – the highest quality fogging system

The A-Line system is different from any system on the market. It uses very durable materials that provide the highest quality for those companies that want to have the best equipment.

The nozzle of the fogging system has a so-called internal micro system, which, among other things, allows working with water under high pressure and guarantees constant flow of water through the nozzle (which is not an easy matter).

The fogging nozzle is made of a ceramic disc with a hole of 3 to 7 microns (20 times stronger than stainless steel), so the water flow is always the same during long use of the system. In addition, when using such a nozzle, the drop of water is so small that it completely evaporates and does not wet the leaves or structures and thus allows very accurately maintain the set humidity of the air.

The nozzle body and parts are made of 316 stainless steel, the strongest material available on the market, and all soft parts are made of Viton material (used in automotive and aerospace components) instead of regular rubber. In addition, each nozzle has a filter inside. The filter protects the nozzle from contaminants larger than 2 microns. The filter can be replaced whenever it is dirty and the frequency of this change depends on the purity of the water used.

Finally, the last feature of the nozzle is that each is equipped with a drip prevention system, so that every time the system stops working, the spring closes the hole, preventing water from dripping from the nozzle.

The massive cross joint is welded directly on the spray pipe, it has double side holes for screwing in the nozzles and a hole for screwing in the next combination of pipe plus cross joint.

Moreover, this way of mounting causes the nozzles to be positioned horizontally along the entire length of the line. The material from which these elements are made is stainless steel. This unique body can be hung directly on the construction of the greenhouse with hooks.

The fogging nozzle is made of a ceramic disc with a hole of 3 to 7 microns (20 times stronger than stainless steel), so the water flow is always the same during long use of the system. In addition, when using such a nozzle, the drop of water is so small that it completely evaporates and does not wet the leaves or structures and thus allows very accurately maintain the set humidity of the air.

The end result is a straight line, spraying water on both sides, distributing a homogeneous amount of water in the environment.

The connection between the main line and the fog line is made by means of high-pressure (160 bar) flexible hoses made of stainless steel and rubber, resistant to oil and other weather conditions. The fasteners are made of stainless steel.

The pump unit is made of the best hydraulic and mechanical and electronic technologies.

The high-pressure pumps are made of stainless steel with ceramic pistons, the motors are self-ventilated and are modulated by frequency controllers for minimum energy consumption.

Fogging system also provides a set of water filters, stainless steel filters with 5 and 2 micron size cartridges, sand filters. The whole system can be integrated with reverse osmosis systems.

The sample pump unit kit includes a stainless steel tank, solenoid valves, pressure sensors, gauges, filters, safety valves and a touch screen on the electrical box.

Each shown system works automatically after connecting the computer to the climate control system, when the environment requires humidity or cooling, the system starts and stops in a configurable way, setting the operating time and the desired humidity level.

It is also possible to provide an autonomous system, i.e. the system will be equipped with temperature and humidity sensors and controls to automatically maintain the desired humidity.

Green Team also offers installation or, on request, supervision during installation.

The maintenance required is very low and mainly involves the replacement of filter cartridges and oil in high-pressure pumps.

The operation of all pressure pumps is controlled by frequency controllers which allows for smooth control of the pump operation depending on the water demand by the installation in a specific section. In the fogging systems offered by Green Team we do NOT use any pressure reducers and bypasses that recycle excess water from the fogging system. This solution eliminates the consumption of electricity for compressing water in the system, which will partly be recycled from the pressure system. In our systems, the pump system delivers exactly the amount of high-pressure water that will be delivered as mist in the greenhouse.

Modern solutions used in the pressure pumps offered by Green Team have significantly reduced the noise emitted by the pumping systems.

Precision humidity control in the greenhouse facility.

The size of all emitted droplets in the range of 3 to 7 microns.

Lowering the temperature in the greenhouse in the summer to 5oC

Much less electricity consumption.

The ability to connect the fogging system even to city water.

Possibility of cooperation of fogging system with climate computer.

The system can be a stand-alone system equipped with its own humidity sensors.

Ability to use an anti-Legionella program.

Ability to remote control of the system using the Internet network.

Low cost of maintenance and trouble-free operation for many years.

No pressure reducers of any kind.

No bypasses and other systems that return excess water from the system.

A compact device equipped with a high-pressure pump (70 -120 bar), which can be combined with any nebulizing system – the one that best suits your needs and requirements. We install these systems wherever climate control with water mist is needed – in gardens, hotels, restaurants, bars, beer gardens, swimming pools, playgrounds.

The range of objects and applications is so wide, because each system can be freely configured and installed according to the specifics, needs and requirements of the given object. The real power of the system is the nozzles, which can spray fine water droplets no larger than 1 micron (thousand per millimeter). This makes us surrounded by a pleasant, gentle mist without any wet traces.

The customer can choose the method of spraying – from high-pressure plastic nozzles to stainless steel nozzles.

Green Team company offers two types of complete fogging systems as standard, which can be used in bars or restaurants. The first system, smaller, is equipped with nozzles from 5 to 15 nozzles and the second, larger, is equipped with nozzles from 15 to 32.

The fogging systems offered are ready-made and easy-to-install systems that stand out for their:

Mobile: +48 609 606 455

Mobile: +48 601 667 537

E-mail: jan.szubski@greenteam.pl

E-mail: marcin.szubski@greenteam.pl