We deliver our water disinfection systems over the whole world at a very good price!

Description of the Green Team UV System work:

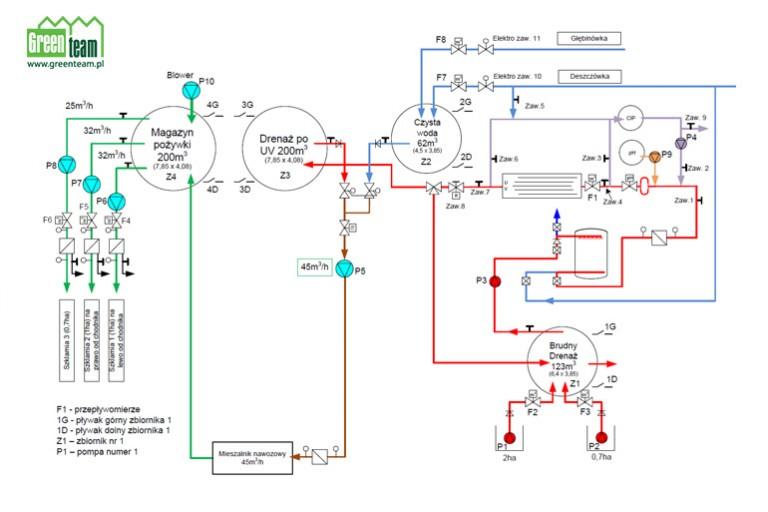

The system proposed by us enables re-use of plant irrigation water in crops under covers. It is built of tanks used for storing clean and dirty nutrients as well as for storing clean water. In the first place, the dirty medium from the glasshouse overflow with drainage pumps is fed into one large tank. Any number of drainage pumps can be connected to such a tank. Each of the pipelines supplying dirty medium is equipped with a separate flow meter, which allows us to control the amount of overflow from a specific part of the greenhouse in any cycle – hourly, daily, etc.

The container for dirty nutrient is also equipped with an overflow system protecting the tank against overfilling. From the tank with dirty medium using a pump, the dirty medium is fed first to the automatic sand filter, then to the disk filter and only at the end to the UV reactor equipped with the appropriate number of lamps.

The number of lamps in the reactor depends on the expected flow of disinfected medium as well as the required UV dose, which we want to achieve in the flowing stream. After starting the recycling system for the first 5 minutes of operation of the UV reactor, the disinfected medium using the three-way valve is returned to the storage tank of the dirty medium.

This way, we are 100% sure that the UV reactor is properly warmed up and only after this time the system automatically changes the position of the three-way valve allows the administration of clean, disinfected medium to the second “clean” tank. In the situation when the UV filter becomes dirty during automatic operation, the UV system will be stopped for the time needed to clean the filter.

Cleaning, rinsing the filter is also carried out automatically and is controlled by measuring the pressure before and after the filter.

After the filter rinsing is completed, the normal operation of the recycling system will be restored automatically.

The disinfection system of the nutrient solution in front of the reactor is equipped with a flow meter that allows the control of the current flow as well as allows adding the amount of disinfected medium.

The occurrence of a lack of flow in the reactor is equivalent to a failure of the pump or filter and the system in this situation will also automatically stop the normal operation of the system by reporting service to the reason for switching off the reactor.

During the operation of the UV reactor in the flow, an appropriate amount of acid is automatically fed, which allows to maintain the stability of the flowing medium as well as slows down the process of deposition of impurities inside the UV reactor.

Our nutrient recycling and disinfection system is additionally equipped with a closed UV reactor cleaning system, which enables the system to be flushed out thoroughly using elevated acid concentrations.

In a situation when the system informs the service about the necessity of washing the reactor, with the help of a closed system additionally equipped with a small CIP tank, in a short time we are able to rinse the UV reactor.

In the next tank, clean water is stored. Our recycling system allows simultaneous topping up of this tank with both rainwater and well water in the appropriate, given volume ratio.

The recycling system then allows mixing of the UV medium with clean water using a mixing valve in the flow so as to obtain the appropriate Ec set up in front of the fertilizer mixer.

Also, obtaining the expected Ec is done automatically.

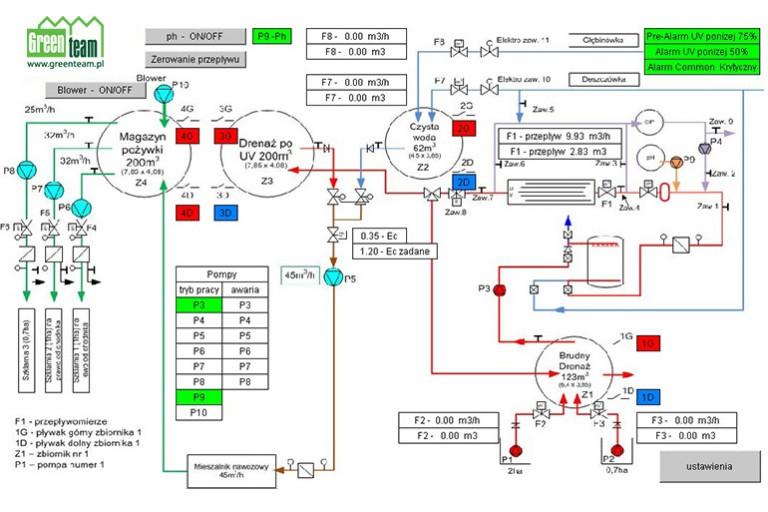

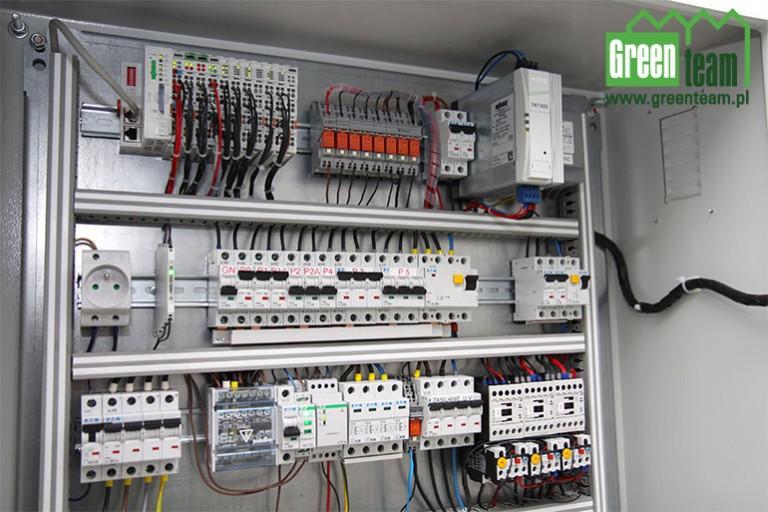

The entire system of recycling described by the user can be observed on-line on his own computer in the office and with the help of this computer he can ask, change the parameters of the recycling system, as well as by information displayed on the computer screen. The service is informed of the current parameters of the system as well as possible failures, e.g. about the protection of any of the pumps is turned on and many other information.

The system has been designed so that the only element of the normal operation of the system is the turning on/off of recycling proces.

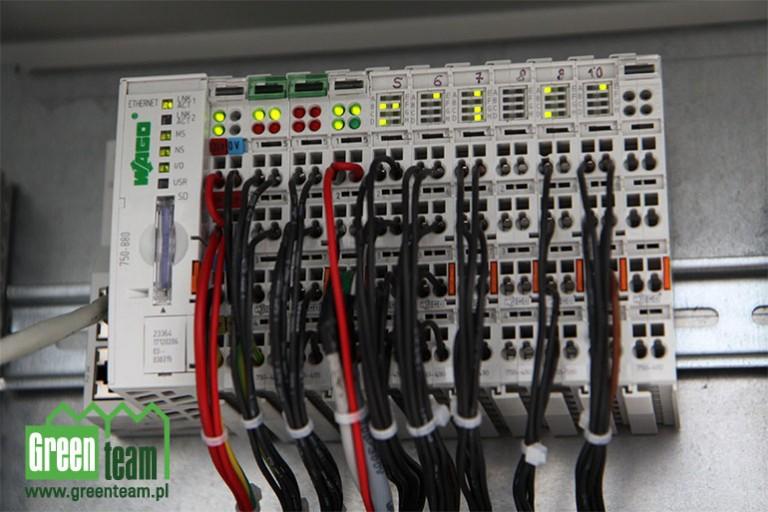

The entire nutrient recycling system was developed and produced by Green Team. Also a computer software that supports the entire disinfection process together with mixing the UV medium with clean water in front of the mixer and computer visualization of the nutrient recycling process were also developed by Green Team. The system is designed to work with any fertilizer mixer.

We are also able to adapt our recycling system to individual user expectations and needs, expanding its capabilities with additional control of other devices.

Security and control:

- Each pump supply system is equipped with a control and signaling of thermals activation and a system of controlling the correct operation of contactors. This information is displayed on the computer monitor and affects the operation of the recycling system or causes its safe shutdown.

- The nutrient flow control system also gives the possibility of adding up the amount of nutrient flow at any time, as well as controlling the correct operation of the entire recycling system.

- Each storage tank is equipped with a water level control system in the form of floats or hydrostatic probes – with the last solution, the computer monitor also displays the amount of stored water or nutrient medium with an accuracy of 1m3. The tank filling level control system also fulfills the role of protecting the operation of the recycling system against dry-running by allowing or blocking the ability to start the system.

- All emergency states of the system work are signaled in the form of information displayed on the visualization on the computer in the office as well as by the sound signal.

The advantages of the Green Team recycling system:

- Simple and clear design of the system.

- Fully automated system operation.

- The system is equipped with a closed reactor cleaning system.

- Possible cooperation with each fertilizer mixer.

- Accurate visualization of operating parameters on the computer screen.

- Possibility to custom adjust the construction and operation of the system to individual needs.

- Competitive investment cost.

- Patented Polish idea, implementation and software.